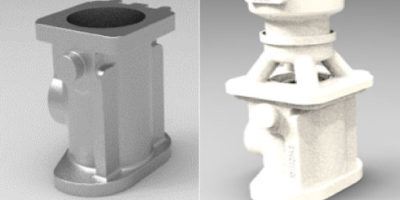

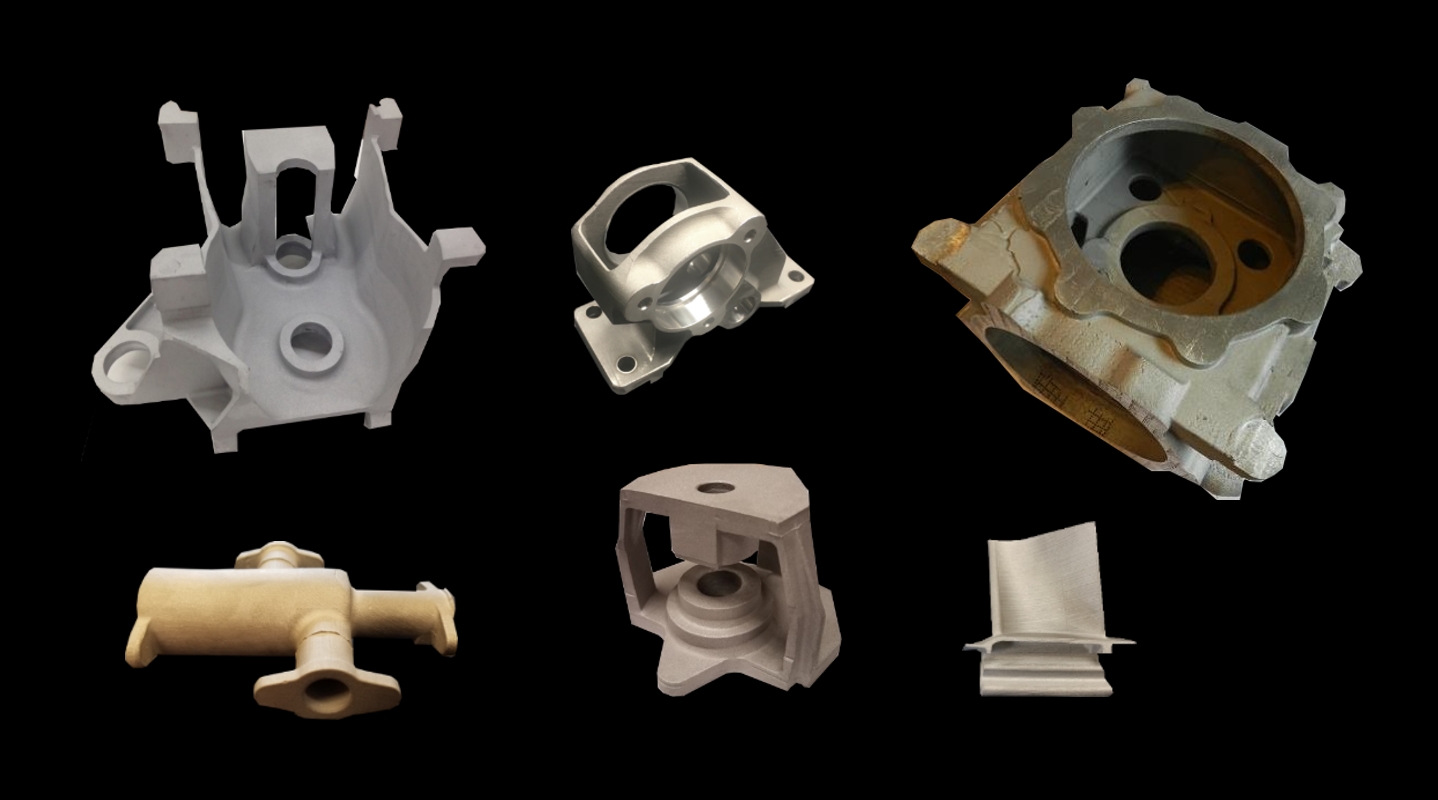

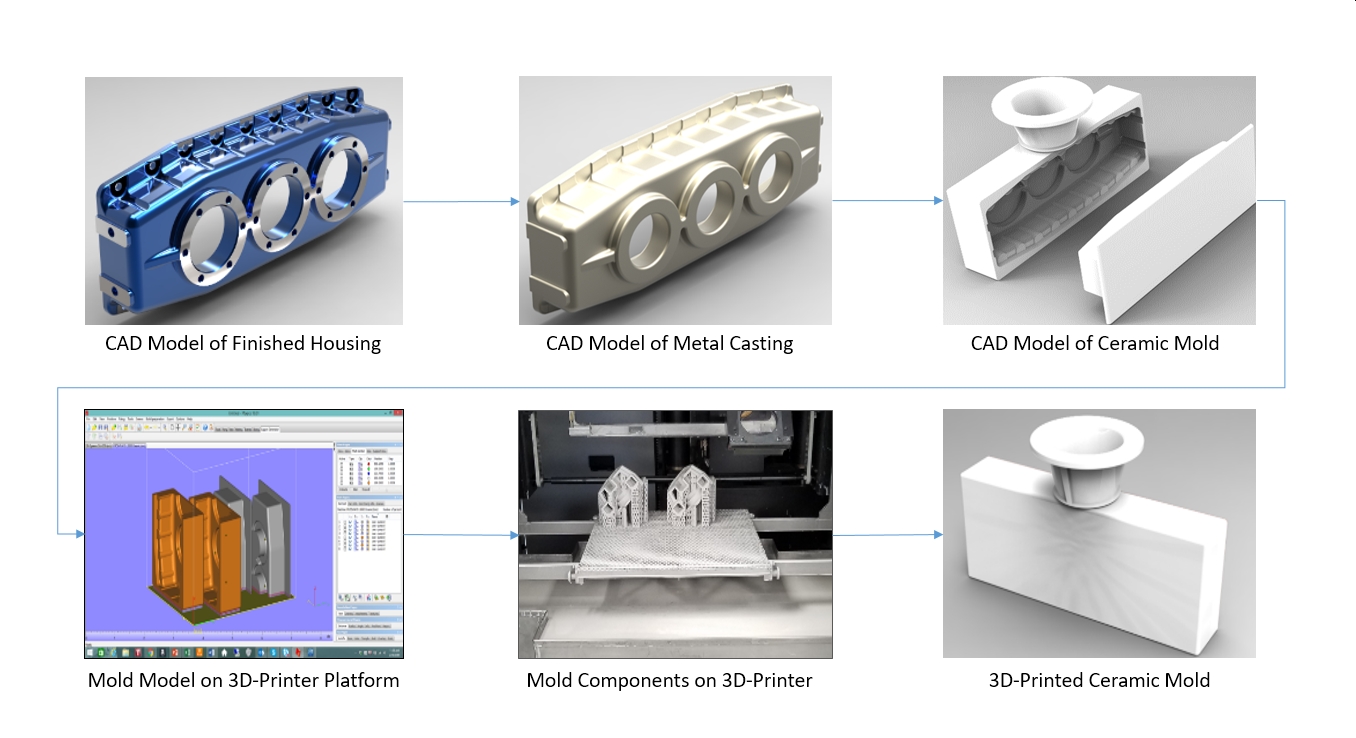

The PERFECT-3D engineering team uses special ceramic materials of silica, zircon, and alumina which have been optimized for ceramic 3D printing and investment casting applications. These 3D printing materials have proven to withstand high-temperatures with various applications.

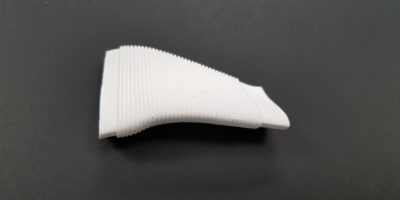

Our industrial 3D printers use the latest in high-precision 3D printing technology to create small and large-scale ceramic components (ranging in size from 1” to 20”) with intricate features (as small as 0.020”).

The 3D printing process at PERFECT-3D involves finely controlled firing and sintering on every ceramic part; so that they are optimized to meet our customers’ specific needs.

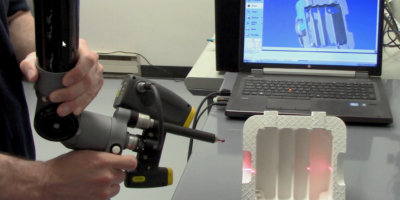

Given the demands of ceramic 3D printing, our 3D printers use the latest additive manufacturing equipment to support advanced compliance-checking as well as reverse engineering.