Renaissance Services Inc., is excited to be a part of the Defense Manufacturing Conference in Nashville, Tennessee on December 11 – 14, 2023. The Defense Manufacturing Conference is the nation’s annual forum for reviewing progress with technologies pertinent to aerospace and defense manufacturing. Renaissance will have an exhibit booth at the conference showing examples of hard-to-get legacy replacement parts that were produced using a combination of reverse engineering and additive manufacturing. In addition, Renaissance will also be presenting more insights about the part replacement process at one of the technical sessions, entitled “Rapid Production of Legacy Cast Parts Using 3D-Printed Ceramic Molds”.

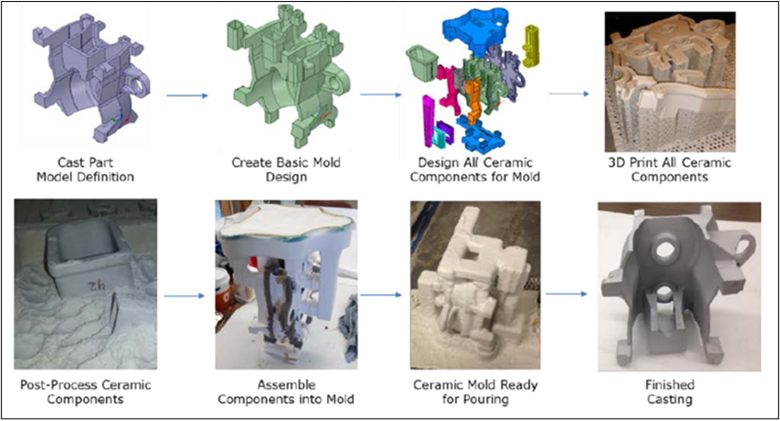

When the Department of Defense has a need for legacy replacement parts that lack any technical documentation, the Renaissance Services team uses scanning technologies and its engineering expertise to create complete MIL-STD-31000 technical data packages. The Renaissance team then uses the ceramic additive manufacturing expertise of its PERFECT-3D division to 3D-print the tooling and process aids to make the cast parts.

While direct metal 3D-printing is very appealing for replacement parts, the additive manufacturing of metal parts requires a very long and costly requalification process. Meanwhile, since the use of 3D-printed ceramic tooling, such as molds for making castings, does not require requalification, 3D-printed tooling avoids this impact on cost and lead time.

PERFECT-3D, a division of Renaissance Services, 3D-prints the tooling to produce castings, which enables foundries to deliver parts with complex geometries to their customers with greatly reduced lead times.

Stop by and visit the Renaissance team at Booth 557 to learn more about the products and capabilities that have produced and delivered multiple legacy parts for the defense industry.

For further information about any of our products, please contact Rick Pressley at (937) 586-7277 or email us at [email protected]