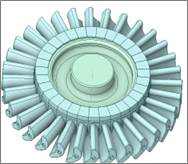

Renaissance Services won the award for most innovative casting in the Defense category at the 2023 Investment Casting Institute (ICI) Annual Conference. The 10” Integrally Bladed Rotor (IBR) was produced using a mold composed of individual airfoils assembled to a 3D-printed hub. The airfoils are 3D-printed ceramic integral molds/cores. The casting was poured in a vacuum using a nickel-based superalloy at the Bescast foundry in Cleveland, Ohio.

The first photo on the left shows a 3D CAD model of the IBR indicating the overall assembly components. The second photo shows the actual nickel casting with cast-in cooling holes. The third photo on the far right shows a bottom view of one of the 3D-printed ceramic airfoil molds with the integral core.

Award Table at the ICI Conference