Join PERFECT-3D For The Ceramics Expo

Suburban Collection Showplace, Novi, Michigan, USA

Dan Sokol will be a Panel Speaker at the Ceramics Expo in Novi, Michigan on May 3, 2023 at 9:30am. The “Ask the Experts Panel” will be providing insights about new advancements and innovations in ceramic materials. Dan will be providing case studies about the application of ceramic additive manufacturing in the aerospace industry, with a specific focus on producing advanced turbine engine castings. Dan will he highlighting some of the methods below.

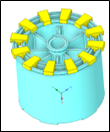

Fig.1

3D-Printed Ceramic Cores

Complex ceramic cores (Fig. 1) can be 3D-printed from your model in weeks. Our process can provide development quantities without expensive tooling. Cores are manufactured from our on proprietary materials and shipped to you ready to use in your process.

3D-Printed Ceramic Molds

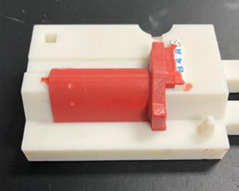

Fig. 3

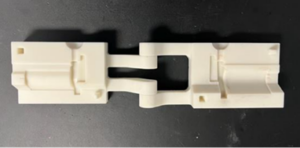

Fig. 2

Ceramic molds can be 3D-printed from your geometry (Fig 2) with short lead times. Our engineering staff will work with you to ensure your design works with our process. These mold designs can be 3D-Printed (Fig. 3) and delivered to your foundry ready to pour. Our process saves valuable time and resources to produce castings.

3D-Printed Wax Dies

3D-Printed wax injection dies can shorten time to get wax patterns for your casting applications. Our

Fig. 4

team at Perfect-3D can design a die for you or assist your team in creating a design that works for our process.

3D-Printed dies can be 3D-Printed to meet your requirements. Benefits included, quick turn time for initial die and replacements. Dies are post processed to you required level. Each injected wax pattern is at the same finish quality as the die, unlike 3D wax patterns that must be individually finished.

Fig. 5

Upon approval of the die, wax patterns can be supplied from the die or the die can be shipped to your facility for injections on site.

Our capability to 3D-Print dies and cores allow PERFECT-3D to provide our customers with wax injected patterns complete with ceramic core. This unique capability provides our customers with quality patterns, with (Fig. 6) and without cores.

Fig. 6

To date these dies have provided injected wax patterns in excess of 500 without die replacement.

Want to know more, please visit https://www.ceramicsexpousa.com/