Renaissance Services had requirements for an Air Force program , which involved reverse engineering and the rapid production of castings in 8 weeks. This involved a complete analysis of the legacy part along with the creation of a Technical Data Package (TDP) for an aluminum support housing. The PERFECT-3D division of Renaissance Services was responsible for creating the 3D-printed tooling in support of making the A356 aluminum casting.

Renaissance Services had requirements for an Air Force program , which involved reverse engineering and the rapid production of castings in 8 weeks. This involved a complete analysis of the legacy part along with the creation of a Technical Data Package (TDP) for an aluminum support housing. The PERFECT-3D division of Renaissance Services was responsible for creating the 3D-printed tooling in support of making the A356 aluminum casting.

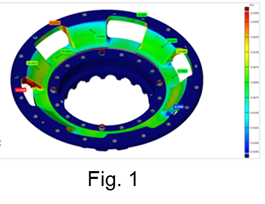

The Renaissance Services team reverse engineered

the part (Fig 1) and supplied MIL-STD-31000

Technical Data Packages including 2D drawings and

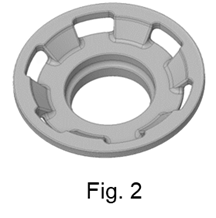

3D CAD models (Fig. 2) to meet Air Force requirements.

The PERFECT-3D team then designed and generated all

CAD data required to produce the 3D-printed molds (Fig. 3).

Working closely with our foundry partner, ceramic molds

were printed on our DLP printers. Components were sintered,

post processed, and inspected. PERFECT-3D delivered

the completed molds to the foundry “ready-to-pour”. The

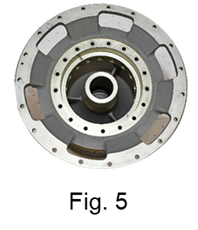

castings (Fig. 4) were produced and delivered to the

machining supplier (Fig. 5) where they were final machined

to make finished parts for assemblies.