Challenge – produce aluminum casting without hard tooling for development program.

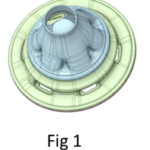

The PERFECT-3D design team produced 3D models of the components required for shell assembly. The shell model was designed from a customer-supplied casting model. We then worked directly with our foundry customer to include all interfaces required for this application as shown in Fig 1. Our shells can also be printed with serial numbers or other identifiers right in the shell (See Fig 2). Each component is designed to optimize 3D-printing and ensure parts can be inspected on all internal areas.

3D-printed ceramic shell components were then printed on our 3D printers using our own ceramic material. Each component is post-processed and inspected in the “green” state prior to moving to the sintering stage.

After sintering, each part (See Figs 3 & 4) is post-processed and inspected. Approved components then move to assembly stage.

All components are dry fit (Fig 5) to ensure proper alignments prior to final assembly. Parts are then assembled and inspected prior to shipment to the foundry.

Once the completed shell arrives at foundry, it is inspected and placed into their normal process. Shells produced castings (Fig 6) from A356 aluminum. Castings were successful and met metallurgical and casting requirements in less than 6 weeks.

Shells provide a great benefit for complex geometries and do not require any draft. Less manpower requirements at the foundry with ready-to-pour molds. Geometries that cannot be generated with the conventional tooling dies can now be cast by taking advantage of our 3D-printed shells.

molds. Geometries that cannot be generated with the conventional tooling dies can now be cast by taking advantage of our 3D-printed shells.