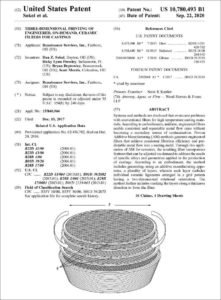

Fairborn, OH – October 6, 2020 – PERFECT-3D, a division of Renaissance Services Inc., announced that the United States Patent and Trademark Office (USPTO) has issued U.S. Patent No. 10,780,493 for three-dimensional printing of engineered, on-demand, ceramic filters for castings. PERFECT-3D uses 3D-printing to produce ceramic cores, molds, and filters for use by foundries that produce investment castings for aerospace and defense applications.

The patent covers PERFECT-3D’s precision ceramic 3D-printing, which enables very tight control of filter production. These 3D-printed filters provide greatly improved metal filtering for foundries, which improves the yield rate of castings. The filters can be any shape including all current standard geometries (tapered, straight-sided, square, rectangular and round) and can range in size from 0.5″ gate filters to 5.0″ pour cup filters. These engineered filters can:

The patent covers PERFECT-3D’s precision ceramic 3D-printing, which enables very tight control of filter production. These 3D-printed filters provide greatly improved metal filtering for foundries, which improves the yield rate of castings. The filters can be any shape including all current standard geometries (tapered, straight-sided, square, rectangular and round) and can range in size from 0.5″ gate filters to 5.0″ pour cup filters. These engineered filters can:

- Overcome problems with conventional filters that tend to introduce inclusions into castings.

- Enable consistent and repeatable metal flow rates without becoming a secondary source of contamination.

- Provide consistent filtration efficiency and predictable metal flow into the mold.

- Tailored to meet specific requirements that can be produced literally “on-demand.”

“PERFECT-3D has developed techniques for 3D-printing high quality ceramic filters for pour cups and runners. This patent further supports our ongoing R&D efforts to produce filters that are the last line of defense against inclusions that result from contaminants in these castings” said Rick Pressley, Director of Programs at PERFECT-3D.

Renaissance’s PERFECT-3D Division produces the 3D-printed ceramic filter, molds, and cores at its fully integrated facility in Fairborn, Ohio.